Automatic Dicing Saw

About

Dicing of substrates into individual units by using a circular saw fitted with a thin diamond blade.

Description

Dicing saw usually refers to the process of cutting processed / unprocessed semiconductor, glass or ceramic substrates into individual units (dies) by using a high-speed diamond blade. The substrate is typically mounted on a metal frame with a sticky tape. Different factors like substrate size, thickness and material, cutting streets determine the dicing parameters including blade selection. DI water is dispensed along the blade trajectory to wash away particles and provide lubrication and cooling.

We offer access to the DISCO DAD 321 dicing saw system for cutting semiconductor, glass or ceramic substrates of size up to 150 mm (6”) in diameter.

Technical specifications:

- Tool: DISCO DAD 321

- Substrate Size: Up to 6” in diameter

- Cutting Specifications:

Uses of rotating diamond blades in a wet environment

Kerf width: from 0.035 to 0.4mm depending on substrate materials and thickness

Cutting depth: up to 3 mm

Cutting speed: 1 – 100 mm/s

Spindle speed: 30.000 rpm

- Position accuracy: < 8 µm (accumulated from 10 line cuts on 4” wafer)

Case study:

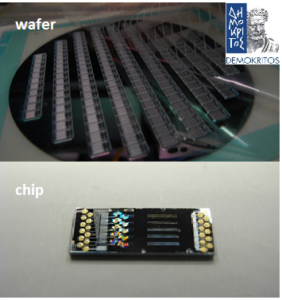

Our dicing tool has been successfully employed for the separation of stand-alone chips originating from EBL and UV-lithography processes at wafer scale. One such case was the FOODsniffer optical biosensor, a complete product developed from A to Z at our facilities.

Access Provider / Facilities