Characterization of Triboelectric Harvesters

About

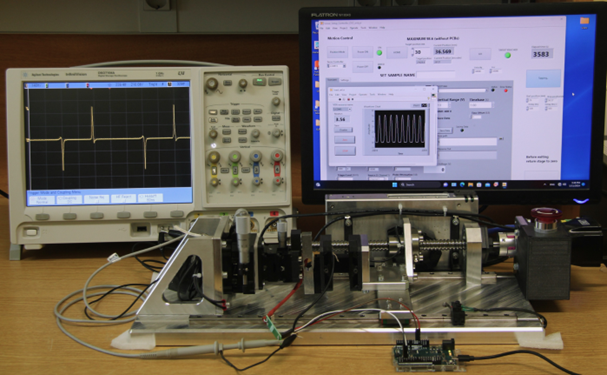

Experimental setup for the characterization of triboelectric harvesters.

Description

Triboelectric energy harvesting is emerging as a main source for the conversion of mechanical energy to electrical for autonomous sensors and systems. NCSR “Demokritos” has developed equipment for the characterization of triboelectric harvesters.

Device characterization consists of:

- a) transient measurements, where the signal of the triboelectric generator is measured during a controlled transient mechanical contact of the two triboelectric surfaces. The movement of the surface is based on a motorized computer-controlled step motor. The velocity and frequency of the motor motion is adjusted according to the desired conditions.

- b) Charging of external capacitor, connected to the triboelectric generator via a bridge rectifier is performed as a function of an external excitation. The energy stored in the capacitor can be used for powering discrete sensors and more complex electronic circuits such a wireless node.

Besides characterization, NCSRD «Demokritos» has the capacity to fabricate a variety of triboelectric devices, at the user request, based on several techniques including flexible technology and 3D printing as well as a variety of surface modification techniques for engineering surfaces roughness (for improved power output) including deposition of nanomaterials, nanopatterning, plasma etching, etc.

Technical specifications:

– Typical sample size: 2x2cm2 (Alternative sample sizes could be also considered)

– Triboelectric devices working on Contact-Separation mode

– Nature of samples: Hard or flexible substrates

– Samples must have metal electrode to the back surfaces

– Operating conditions: room temperature

– Force contact between triboelectric surface: 5-100Nt

– Frequency: 1-5Hz

– Output parameters: Open Circuit Voltage, Short Circuit Current and Maximum power vs External Load, Capacitor charging as a function of the excitation signal.

Test samples can be prepared at the user request including flexible substrates (Kapton, PET, FEP, etc), 3D printed substrates (PLA). Possibility of surface modification techniques for engineering surfaces roughness is possible (including deposition of nanomaterials, nanopatterning, plasma etching, etc.)

Case study:

- A user wants to evaluate and optimize triboelectric harvesters based on flexible substrates. Detailed characterization can be provided to assist in the selection of the optimum materials.

- A user wants to evaluate different surface topographies/roughness. Test structures can be fabricated and characterized following user’s specifications.

Optional:

Influence of SiC and ZnO Doping on the Electrical Performance of Polylactic Acid-Based Triboelectric Nanogenerators, S. Skorda, A. Bardakas, G. Vekinis, C. Tsamis, Sensors 24 (8), 2497 (2024), https://doi.org/10.3390/s24082497

Zinc Oxide-Based Rotational–Linear Triboelectric Nanogenerator, A. Bardakas, A. Segkos, C. Tsamis, Applied Sciences 14 (6), 2396 (2024) https://doi.org/10.3390/app14062396

Design of a flexible tactile sensor for material and texture identification utilizing both contact-separation and surface sliding modes for real-life touch simulation, V. Zacharia, A. Bardakas, A. Anastasopoulos, M.A. Moustaka, E. Hourdakis, C. Tsamis, Nano Energy, Vol. 127, August 2024, 109702, https://doi.org/10.1016/j.nanoen.2024.109702

Access Provider / Facilities