Cryo-Ultramicrotome

About

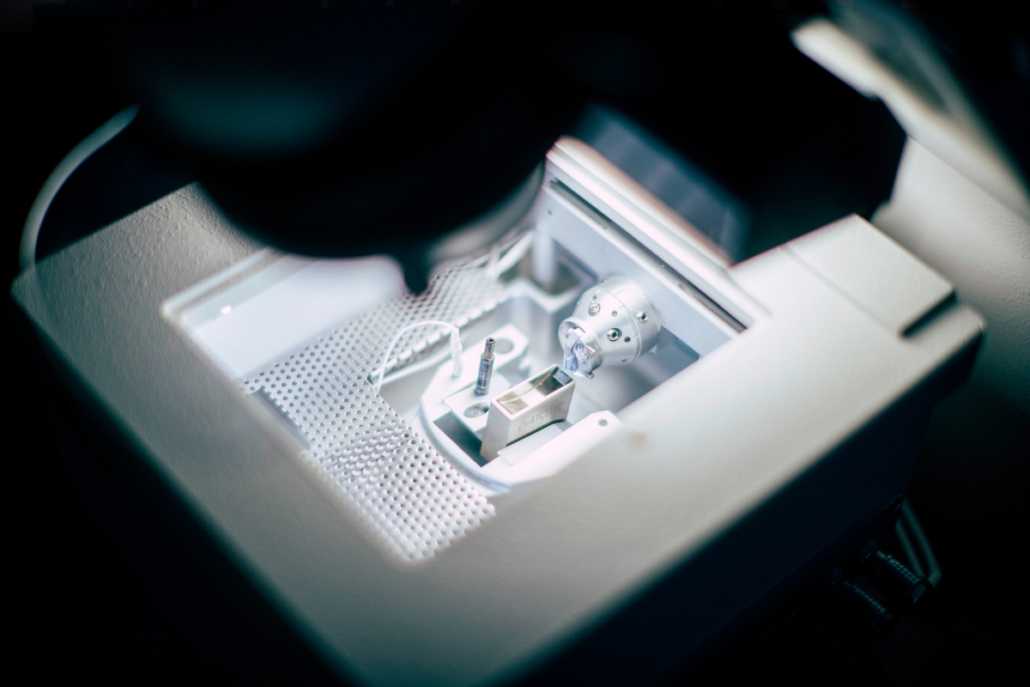

The RMC Power Ultramicrotomy from Boeckeler is used to create cross-sections of materials or layer systems for quick and reliable quality/quantity assessments. These cross-sections have a uniform thickness and extremely smooth surfaces to be analysed by means of advanced techniques such as scanning and transmission electron microscopy or atomic force microscopy.

Description

The ultramicrotome consists of a knife block fitted with a glass or diamond knife, a specimen holder with an advancement mechanism and options for setting the cutting parameters. While the sample is being moved on a circular path, a very precise adjustment mechanism incrementally brings the sample closer to the knife, enabling sections to be cut with a controlled thickness, typically in the range of 200 nm to 1 µm.

Technical specifications:

The sample dimensions are at 5mm x 5mm. To avoid being deformed or even destroyed during the cutting process, the sample must remain stable against the knife blade. Hence, either the samples are embedded in epoxy resins for stabilization, or they are physically hardened by cooling with liquid nitrogen below their glass transition temperature (cryo-ultramicrotomy).

- Ultramicrotome with knife block, specimen holder with an advancement mechanism, options for setting the cutting parameters

- Sections with a controlled thickness (200 nm – 1 µm)

- Sample dimensions at 5mm x 5mm

- Samples physically hardened by cooling with liquid nitrogen

Link for additional information:

Company: https://www.boeckeler.com/

Distributor: https://www.scienceservices.de/rmc-ultramikrotom-powertome-ptxl.html

Case study:

Printed thin film PVDF – Trfe sensors typically host multiple layers on PET substrates. A layer stack might be prepared by screen printing and strong enhancement of the piezo responds results from alignment of the polar domain within an electrical field. Using AC-poling hysteresis loops provide information on the remanent polarization. A user experiences dielectric breakthroughs as the voltage exceeds 400V when the samples are prepared on a new type of PET substrate. For sufficient poling at least 600V would be required. After identifying some issues together with the Joanneum team, it is decided to use microtome sample preparation techniques. This allows to prepare a sharp cut through the multilayer. Facilitating then SEM measurements the information on the thickness of the individual layers is then extractable as well as inhomogeneities. On the inspection of the samples voids were identified which can be related to poor wetting of the PEDOT:PSS layer on this new PET substrate.

Access Provider / Facilities