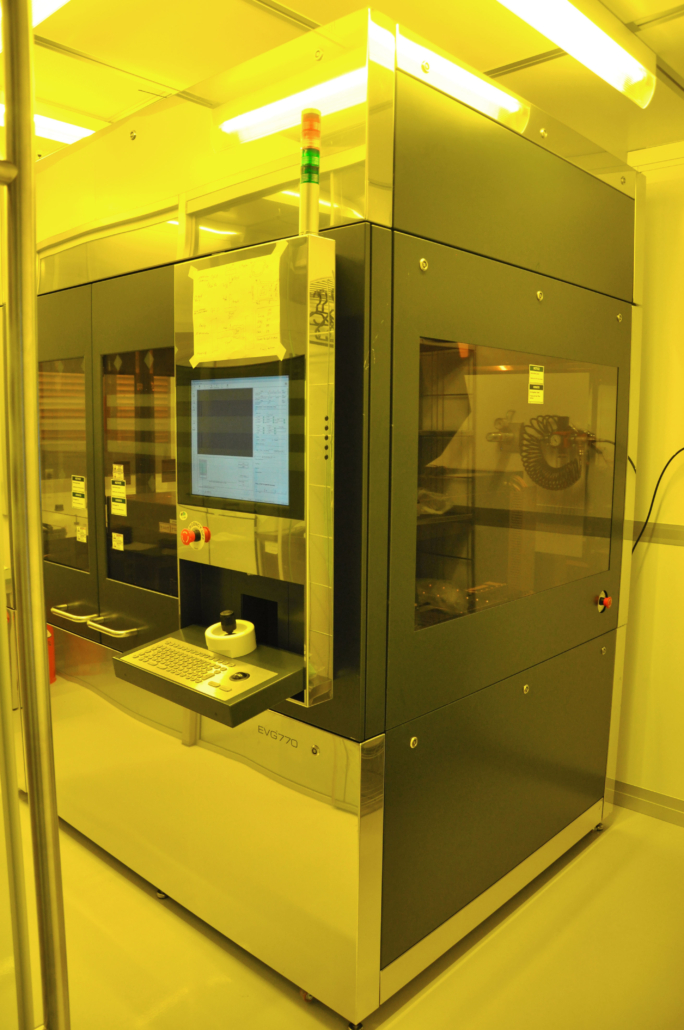

Foil Stepper EVG770

About

Step+Repeat UV imprint machine for pattern upscaling to generate large flexible stamps for roll-to-roll and roll-to-plate imprinting.

Description

The Step+Repeat UV imprint tool is a customized EVG770 stepper with the possibility to load large foil substrates and is located in a micro-cleanroom. The machine enables successively replicating micro- and nanopatterns with high positioning accuracy. Two basic principles for an upscaling process can be applied:

- a) the single fields are replicated with a defined distance to each other and featuring unpatterned gaps in between

- b) seamless stitching of the single fields, where the adjacent fields are positioned precisely in contact to one another, i.e. with negligible gaps, leading to real area upscaling.

The machine is equipped with two dispenser types, a top dispenser for droplet application of the resin onto the substrate, and a bottom dispenser, that allows coating of the stamp. The second type is preferable for patterns with a high cavity volume. Resin exposure can be done via a low-power broadband UV lamp or a high-power UV LED.

The direct result of the process is a “polymer shim” (a large-area resin-on-foil stamp). If needed, we can help organizing galvanization at external companies of this polymer shim to fabricate a durable nickel production stamp/tool. However, the “bare” polymer shims are directly suitable for shorter test production runs in our R2R imprint pilot line.

Link to JOR-Homepage:

Technical specifications:

Specifications:

- Active area of single pattern field: 10´10 mm² to 50 mm²

- Maximum polymer shim size: 700´380 mm²

- Positioning accuracy of the stage: 3 µm over an area of 300´300 mm²

- Micro-cleanroom with particle control and temperature stability of ± 1°C

Case study:

1) A user has a 2.5D pattern available, on a Si/Ni/quartz master sized 20´20 mm². The targeted product has already proven as a prototype and should now be fabricated via roll-to-roll UV nanoimprinting. JOANNEUM RESEARCH will fabricate a step+repeat working stamp containing the 20´20 mm² pattern field and replicate the pattern to fill a flexible polymer stamp with over 200 identical fields. This polymer tool can be directly used for a R2R test run.

2) A user has a nanopattern available, on a Si/Ni/quartz master sized 15´30 mm². The targeted product demands for a continuously patterned field of 100´100 mm². JOANNEUM RESEARCH will fabricate a step+repeat working stamp containing the pattern and replicate it in a seamless manner. The patterned field can be directly delivered to the user for use or further manipulation.

Access Provider / Facilities