R2R UV-Nanoimprinting

About

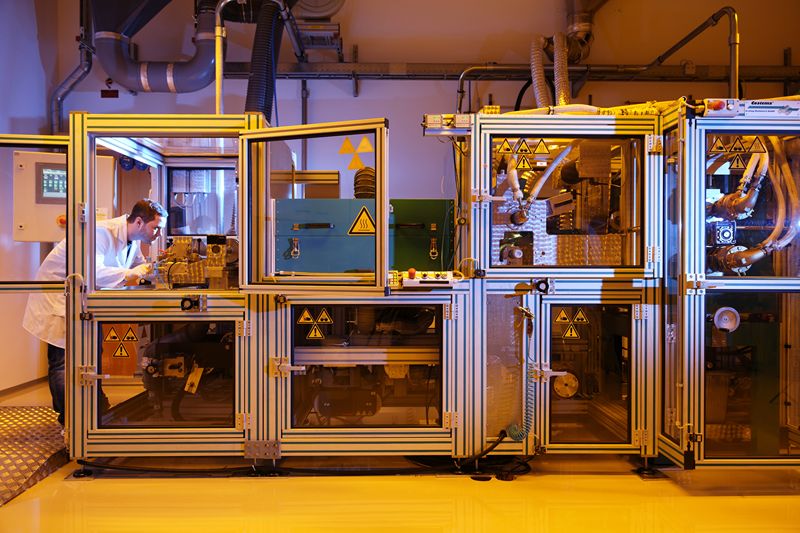

Our roll-to-roll nanoimprinting machine facilitates continuous and therefore cost-effective production of micro- and nanopatterns on large-area flexible substrates.

Description

With the R2R UV-Nanoimprinting machine we can produce micro- and nanostructures at high throughput (m/min) and over large areas (m2) continuously on transparent flexible substrate rolls. For this purpose, first a UV-curable imprint resin layer is applied on the substrate by gravure or slot-die coating. The coated web is then conveyed to the imprint roller wrapped by a flexible stamp, that transfers its relief of micro- or nanostructures into the wet resin layer. At the same time, the resin structures are cured with a UV lamp from the back through the transparent substrate.

We have realized 100 nm fine conductive interconnection lines, freeform microoptical 2.5D structures for light management, microfluidic channel structures for biosensors and different types of bionic nanostructures for drag reducing, antireflective, superhydrophobic and antimicrobial surfaces.

Technical specifications:

Supplier: Customized Basecoater 44 from Coatema

Specifications:

- Throughput: web speed of 0.5 – 30 m/min

- Substrates: transparent films width 280 mm (PET, Cellulose, PMMA, PC, PS, COC …)

- Coating thickness: resist coating (gravure printing / slot die coating) range 500 nm – 200 μm

- UV imprinting with UV LED irradiance (max. 14 W/cm², 365 or 395 nm)

- UV imprinting line pressure at max. 60 kN/m

- UV lamination

- Pre-treatment: Corona with 1000 W

- In-line characterization: white light interferometry (200 nm – 200 μm) for wet coating thickness measurement and line scan camera with 5 μm resolution for inline optical characterization

- Feature sizes: in xy: ≥ 50 nm, in z: ≤ 200 µm

Link for additional information:

https://www.joanneum.at/materials/en/research-infrastructure/rolle-zu-rolle-nanoimprint-anlage/

Case study:

A user from a hospital supplier wants to have several tenths or hundreds of meters of imprints with antimicrobial structures in a hydrophobic resin on PET film. The user also wants to test, if the preferred structure designs can be fabricated by Joanneum Research’s R2R machine (10-20 days project).

The user has to be aware of the following boundary conditions: The desired features must comply with our design guide lines – but they often can be adjusted accordingly. Prior to imprinting, a Ni stamp with the desired (inverse) antimicrobial features needs to be fabricated with the dimensions of approx. 628 x 280 mm. This has to be done by an external company. And a suitable UV imprint resin has to be selected or developed according to the customer’s specific requirements (NILcure). In evaluation trials, the selected combination of resin and substrate needs to be tested to obtain the optimal parameters for the imprinting process. If these trials lead to a proper process and have been approved by the user, the several tenths or hundreds of meters can be fabricated

Please note that, as outlined in the technology chain descriptions (Technology Chain Microoptics), the mastering and upscaling process of structures to a polymer stamp, which can be used as an intermediate master for Ni galvanisation, can also be provided by Joanneum Research.

Optional:

- Götz et al., ACS Appl. Nano Mater 5, 3434–3449 (2022)

- Tören et al., Lab Chip 20, 4106-4117 (2020)

- Leitgeb et al., ACS Nano 10 (5), 4926 (2016)

- Nees et al., Proc. of SPIE Vol. 9777, 97770D, doi: 10.1117/12.22181 (2016)

Access Provider / Facilities