Smart Systems Design, Characterisation and Prototyping Facility

About

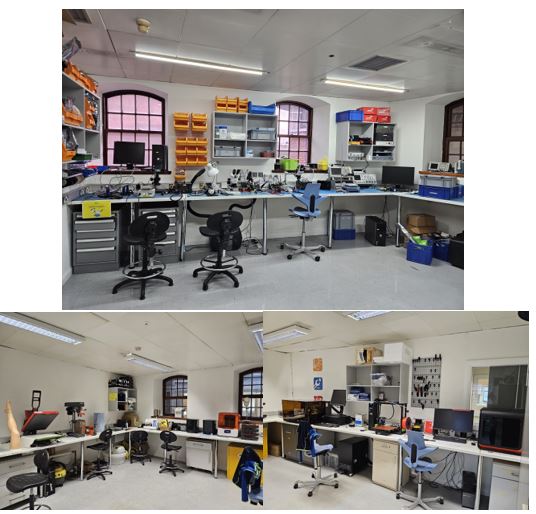

This is a suite of test equipment that offers a turnkey electronics system design, manufacture, test and characterisation prototyping facility. Incorporating PCB Design capability, 3d printing and full high speed electronics testing capability.

Description

The Human-Centric System Cluster in Tyndall, in particular, has the vision to enable sustainable well-being for healthy populations by developing next-generation human-centric wearable systems by leveraging the core technology platform capabilities available in body-centric communication, human-computer interaction, flexible electronics, embedded systems (hardware-software codesign) and AI. The technological advances to build such wearables, the unique role of underlying AI, and how these can transform our everyday lives are the main research focus of Tyndall’s edge AI team.

Within Tyndall’s Human Centric Systems Cluster, the NTG group is an interdisciplinary team with backgrounds in chemical, physical and life sciences, and electronic and micro-electronic engineering in the development of VOC sensor transducers and the WSN group has significant expertise in integrating such sensors in to demonstrator prototypes.

The WSN groups expertise lies in hardware software codesign for Embedded systems prototype development, Sensor integration, wireless communications, energy management for development of prototype technologies for in field testing incorporating edge AI and machine learning algorithms.

Technical specifications:

Electronics Characterisation design and prototyping facility, precision 3d printers, laboratory for the synthesis and processing of nanomaterials. UV-vis characterisation and electrochemical characterisation, laboratory with microscopy facilities, SEM, Raman facilities also available in the group.

3D printers, basic milling and mechanical fabrication tools, as well as essential electronic testing and development equipment (such as oscilloscopes, function generators, and soldering stations) and specialised tools for textile-based sensors fabrication & testing.

| SLA 3D Printed | Formlab | Form 3+ |

| Heat gun | Maplin | N81LG |

| Solder Fume Extractor | METCAL | BVX-100 |

| Hand Wheel Sealer | 801HW | |

| 3D Printer | MakerBot | |

| FDM 3D Printer | Tiertime | UP BOX+ |

| Inkjet Printer | Pixdro | LP50 |

| 3D Printer | Prusa | MK4 |

| Ultrasonic Cleaner | Shesto | UT801/EUK |

| Drill Press | Clark Metalworker | CD P1518 |

Table.1 Electronic Design, Test, Prototyping and Characterization Suite

Case study:

An INFRACHIP user can Design, Manufacture Test and characterise Embedded systems prototypes incorporating all the necessary building blocks to bring their research to life and deploy it in real world environments.

Access Provider / Facilities