Environmentally friendly inks

About

UNINOVA offers the access to the entire value chain related to the production and characterization of environmentally friendly inks made through different synthesis routes and with properties suitable for different deposition techniques (coating and printing).

Description

Core competences offered:

- Synthesis of nanostructures (metallic and metal oxides) with tunable shapes and sizes.

- Production of inks using different synthesis routes (sol-gel, combustion, solvothermal).

- Preparation of different types of inks (solutions, nanoparticles based and, pastes).

- Preparation of inks with adaptable rheological properties using non-toxic solvents.

- Inks characterization.

Major tools:

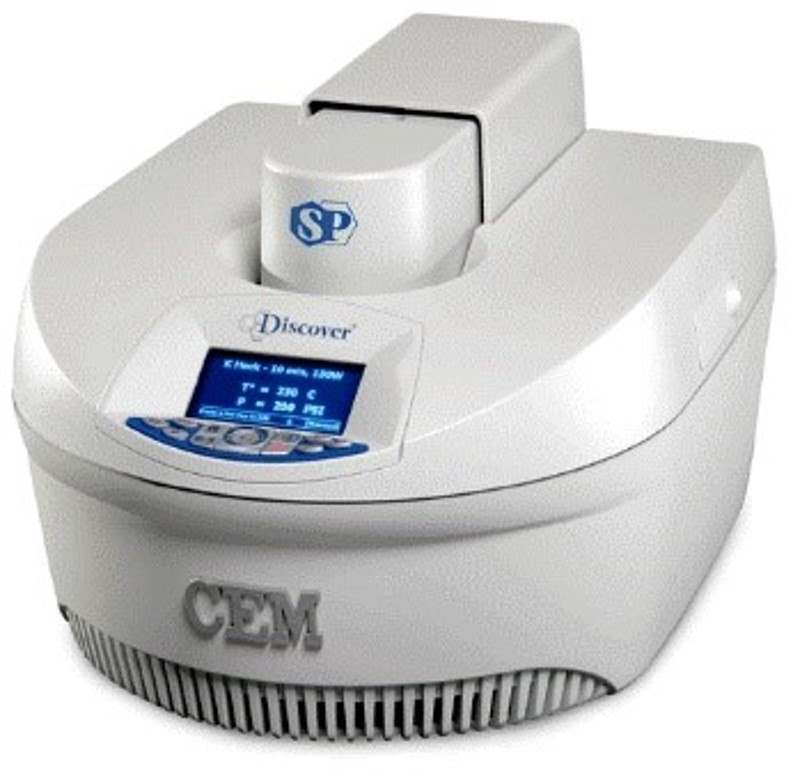

- Synthesis of nanostructures: conventional furnaces, microwave synthesizer, autoclaves, centrifuge, hotplates, magnetic, mechanical and ultrasonic stirrers for ink preparation.

- Inks and nanostructures Characterization: FTIR, UV-VIS Spectroscopy, Contact Angle, Viscometer and DSC-TG for inks. Additional tools for nanostructures characterization include SEM, EDS, EBSD, STEM, AFM, XPS, XRD, micro-Raman.

Technical specifications:

- FTIR–ATR: diamond crystal with wavenumber range between 400 cm-1 and 4000 cm-1; sample volume 0.5 mL.

- UV-VIS Spectroscopy: wavelength range between 200 nm and 2500 nm; sample volume between 1 mL and 3 mL.

- Contact Angle: sessile and pendant drop methods; sample volume 1 mL.

- Viscometer: viscosity range between 5 cP and 44 000 cP; sample volume 1 mL.

- DSC-TG (Simultaneous Thermal Analysis): temperature range between 25 °C and 1000 °C in air or nitrogen atmosphere; sample size 0.5 mL.

Access Provider / Facilities