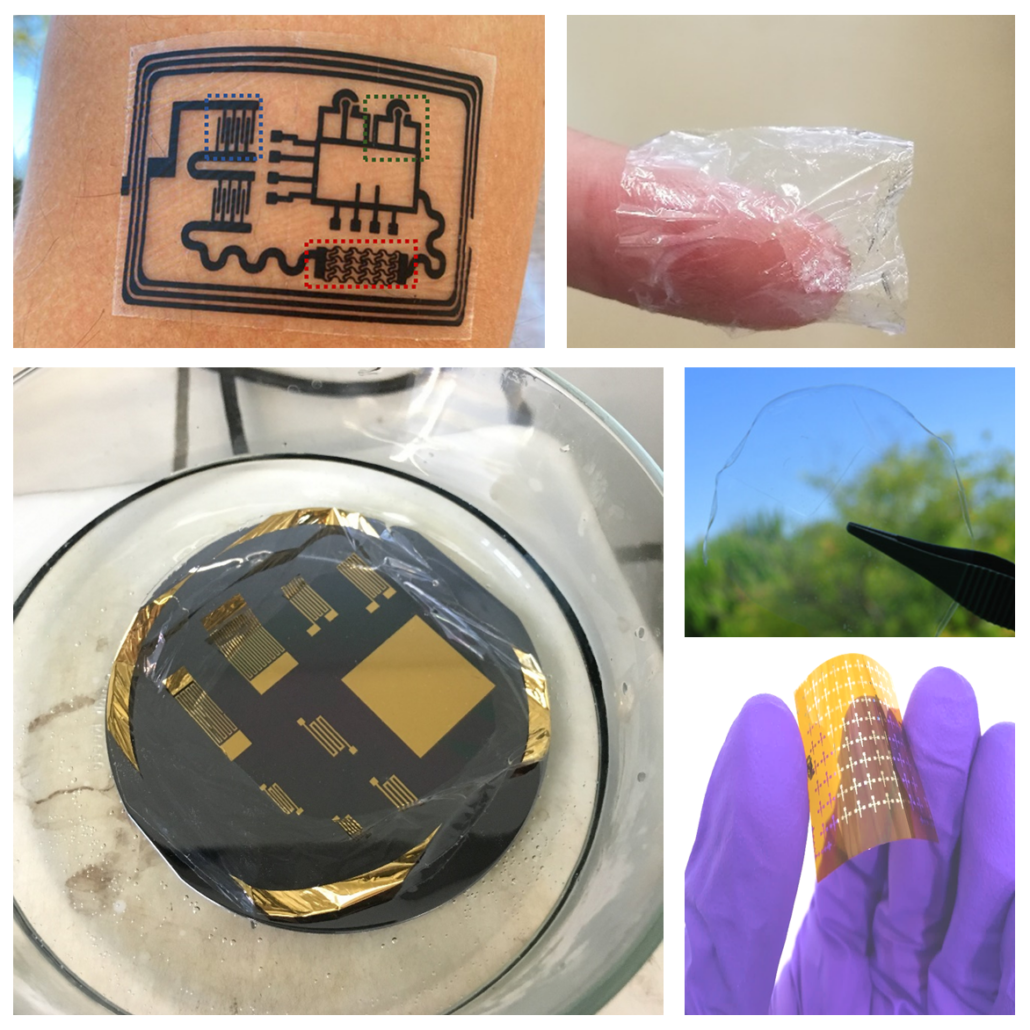

Flexible substrates

About

UNINOVA provides a comprehensive suite of resources encompassing all aspects of flexible substrate production and analysis, from choosing the adequate material to the manufacturing process.

Description

Core competences offered:

- Techniques for substrate production based on diverse materials (commercial polymers and bio-based homemade)

- Assist on material selection and consequent substrate fabrication technique to be used

- Characterization of the substrates used, from morphology, composition and mechanical properties

Major tools:

• Additive manufacturing and printing tools: 3D Printing, 3D Bioprinting

• Coating techniques: Spin-coating and blade coating

• Material characterization tools: SEM/FIB, XRD, DSC-TG, FTIR, XPS, STEM, Raman Spectroscopy, UV-VIS-NIR Spectroscopy, and Optical Microscopy

Technical specifications:

- Up to A4 size (210 mm x 297 mm) depending on the deposition technique;

- Substrate curing: Room temperature, thermal annealing (hotplate and oven), Infrared oven and UV irradiation (248 nm and 365 nm wavelength), combining thermal annealing and UV irradiation (up to 200 °C). The curing method will depend of the materials used to make the substrate.

Case study:

A user has the requirement to know the substrate she/he wants to develop or already available in UNINOVA research centre. Based on this the user will be able to fully characterize the substrate prepared for further use in a specific application.

Optional:

Parylene substrate applications (https://doi.org/10.3390/polym15102277)

Nanocrystalline cellulose (https://iopscience.iop.org/article/10.1088/0957-4484/25/9/094008/meta)

Recycled newspaper for sensors (https://doi.org/10.1016/j.cej.2023.147995)

Paper tags (https://doi.org/10.1016/j.nanoen.2022.107021)

Cork (https://iopscience.iop.org/article/10.1088/2058-8585/ac8e7b/meta)

Access Provider / Facilities