High temperature processes

About

High-temperature processes (boron diffusion, oxidation, LPCVD, and thermal annealing) in furnace, and rapid thermal processing.

Description

We offer high-temperature processes: boron diffusion, wet and dry oxidation, annealing, and LPCVD

of batches of silicon substrates in a controlled and reproducible manner. Ability to obtain good quality thermal oxides in the thickness range from single nanometres to micrometers. LPCVD of polysilicon and silicon nitride films is available.

We also offer rapid thermal processing (RTP, RTO, RTN) of single substrates with a maximum temperature of 1400 °C in various gas atmospheres.

Technical specifications:

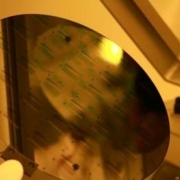

Thermal oxidation (Thermco HTR system 2803 – furnace)

- wet oxidation at temperatures up to 1200 °C,

- dry oxidation with low oxygen flow at temperatures up to 1000 °C,

- the possibility of reproducibly processing large batches in a single process: 25 substrates of 200 mm diameter and 50 substrates of 100 mm and 150 mm diameter.

Diffusion (Thermco HTR system 2803 – furnace)

- boron diffusion at temperatures up to 1000 °C,

- process large batches in a reproducible manner in a single process: 25 substrates of 200 mm diameter and 50 substrates of 100 mm and 150 mm diameter.

Thermal annealing (Thermco HTR system 2803 – furnace)

- annealing in the atmosphere of nitrogen, argon and/or a mixture of nitrogen and hydrogen at temperatures up to 1200 °C,

- process large batches in a reproducible manner in a single process: 25 substrates with a diameter of 200 mm and 50 substrates with a diameter of 100 mm and 150 m.

LPCVD (Thermco HTR system 2803 – furnace)

- CVD process under reduced pressure of polysilicon at temperatures up to 900 °C,

- CVD process under reduced pressure of silicon nitride at temperatures up to 900 °C,

- reproducible processing of large batches in a single process: 25 substrates of 200 mm diameter and 50 substrates of 100 mm and 150 mm diameter.

Rapid thermal processing system (AnnealSys AS-Master)

- RTA, RTO, RTN,

- annealing of 4″, 6″, 8″ substrates with rates up to 200 °C/s,

- annealing of irregularly shaped substrates at a rate of up to 20 °C/s,

- Maximum process temperature: 1400 °C,

- processing in gas atmosphere of N2, Ar, O2, H2, NH3, N2O,

- annealing under reduced pressure possible.

Case study:

A user can deposit a SiN layer by LPCVD for subsequent fabrication of photonic integrated circuits, perform the implant annealing or ohmic contact annealing.

Access Provider / Facilities