Photolithography

About

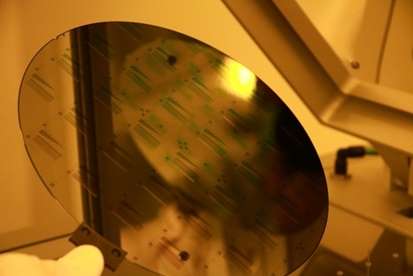

UV photolithography process with um resolution for patterning the predefined shapes in a photoresist.

Description

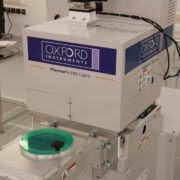

We offer the complete photolithography process, starting from substrate preparation, spin-coating of the resist layer, exposure and development, and hardening. Top-side (TSA) and back-side (BSA) alignment are available (EVG6200NT/200/TB). Repeatable semiautomatic coating and development process (EVG101). Positive and negative tone resists are available for various applications.

Technical specifications:

• working with round substrates up to 200 mm (50 mm/2″, 100 mm/4″, 150 mm/6″, 200 mm/8″) and pieces no smaller than 10 mm x 10 mm,

• top-side alignment (TSA) with an accuracy of 0.5 µm and the back-side alignment (BSA) with an accuracy of 1.0 µm,

• exposing by proximity, contact (soft contact, hard contact), and vacuum contact,

• compatibility with mask sizes of 2.5″x2.5″, 5″x5″, 7″x7″, 9″x9″,

• possible exposure wavelength: 365nm, 434nm,

• exposure in constant-time and constant-dose mode, also constant-dosage mode also in intervals.

Case study:

A user would like to perform a photolithography process to pattern a predefined shape (e.g., waveguide) onto a semiconductor substrate for further processing steps (etching, deposition, etc.).

Access Provider / Facilities