Advanced Dry Etching Platform

About

Myfab Chalmers offers several tools and ready-to-use recipes for etching of diverse materials and applications.

Description

The following processes are already established and run within the infrastructure:

– Ion beam milling

– Reactive ion beam milling

– Deep Si etch (Bosch process) for deep anisotropic etching of Si

– Shallow Si etching with high anisotropy (90deg) and smooth sidewall

– Dielectric etching of SiO2, SiNx

– GaAs etching of high aspect ratio nanostructures

– Compound semiconductor etching at high temperature

– Etching of unconventional materials, such as 2D flakes (TMDC, graphene, …)

– Isotropic Si etching using XeF2 gas vapor

Technical specifications:

Physical etching

- Oxford Ionfab 300 Plus Ion Beam System. Inert Ar ion milling with SIMS endpoint detection. Etching using LN2 cooling available. 5mm to 100mm wafer.

- Oxford Ionfab 300 Reactive Ion Beam System for Chlorine based reactive ion-beam etching. 5mm to 100mm wafer.

ICP-RIE

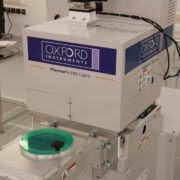

- Oxford PlasmaPro 100 cluster. Double chamber ICP-RIE etching tool with separated Cl-based and F-based etching chemistry. 5mm to 100mm wafers. End-point detection.

- STS ICP-RIE dry etcher with load-lock. HBr, Cl and SF6 etching gases. 5mm to 100mm wafers. High temperature stage for compound semiconductor etching. End-point detection.

- Oxford Estrella for deep Si etch (Bosch Process). 5mm to 150mm wafers. Electrostatic clamp and substrate temperature control.

Vapor etching

- Memstar XeF2 vapor release etching allows dry isotropic etching of Si at μm/min etch rates. 5mm to 150mm wafer.

Access Provider / Facilities