Hybrid Chip-Integration Laboratory

About

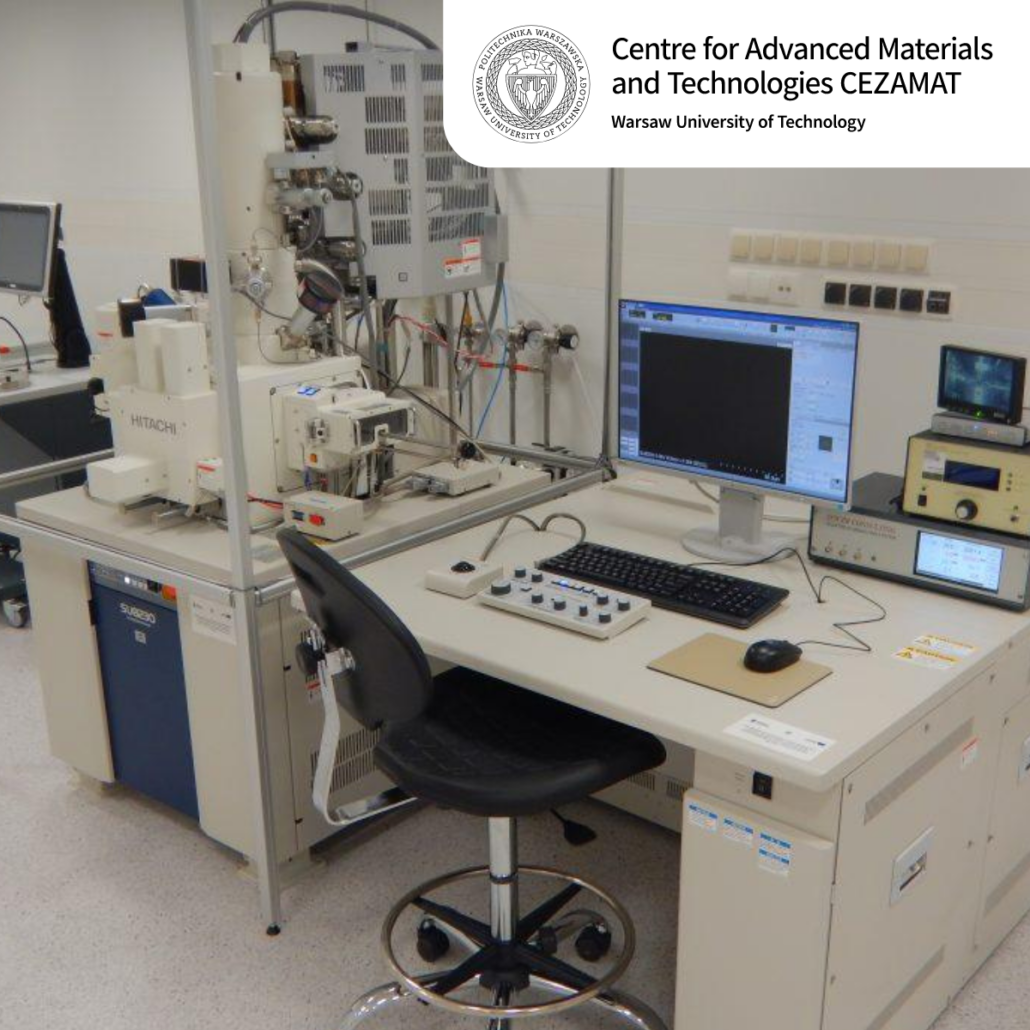

In this laboratory we offer electronic assembly with the use of our Finetech Flip-Chip Pico device. Our equipment and materials allow for use of low temperature joining technique. Mechanical properties testing, thermal shock chamber and SEM imaging allow for an in-depth analysis of the fabricated devices.

Description

The Department of Printed Electronics, Textronics and Assembly has technologies based on its own pastes with silver nanoparticles and possible addition of nanocarbon materials, for applications in high-power printed electronics and electronic assembly. Thanks to the work of the scientific team, it is possible to modify the material in terms of various applications to the substrate, e.g. for screen printing, stencil printing or applying the material with a dispenser. The possibilities of the chemical laboratory are described above.

To perform the assembly, the team uses a Finetech Flip-Chip Pico device or a small, self-built heating press, allowing for multiple connections to be made at the same time. For sintered materials, the assembly is carried out using the Low Temperature Joining Technique adapted to the material. It is possible to make sintered metallic joints at temperatures up to 400°C and at pressure up to 10 MPa. In the case of silver pastes developed by the team, with a temperature exceeding 300°C and a pressure of 5 MPa, it is possible to obtain electrical and thermal conductivity of 50% of bulk silver. Silver joints meet the “Military Standard” (MIL-STD 810) requirements of shear strength. The developed materials allow for operation at high currents, at temperatures exceeding 600°C.

Our team’s VJ60 and VJ70 adhesives facilitate low-temperature assembly, curing at 120°C, 50°C, and room temperature for versatile application. Tested on various substrates including copper, PC, thermal shrinking foils, cotton, and paper, they ensure reliable bonding across diverse materials. Demonstrating exceptional conductivity, sheet resistance at 60°C measures approximately 18 mΩ/sq, and remains impressively low at around 115 mΩ/sq even at room temperature (VJ70), ensuring consistent performance across temperature variations. Boasting a shear strength of approximately 3.7 MPa (VJ60), these joints provide robust connections suitable for demanding applications. Notably, they offer flexibility, stretchability, and resilience, enduring rigorous washing machine cycles, highlighting their durability and suitability for diverse environments.

Layers and assembly may be characterized by the CEZAMAT equipment. Shear strength and adhesion parameters may be tested using a single-column tensile machine. These machines may also be used to perform cyclic bending and stretching tests of applied layers and joints on flexible substrates. The porosity of the metallic layer may be tested with use of Scanning Electron Microscope and checking the amount and size of pores of the layer shown in the SEM pictures. The thermal conductivity of metallic layers is determined on the basis of found porosity. Thermal conductivity can also be determined using a comparative method using a thermal imaging camera. With the thermal shock chamber it is also possible to test the impact temperatures in a range -40 – 120°C on the layers and joints parameters.

Technical specifications:

– Flip-Chip positioning precision up to 5 μm, arm pressure up to 40 N, max. heated bad temperature 400 °C.

– SMD size no smaller than 0201 components,

– low temperature sintering can be conducted up to 400 °C,

– shock chamber temperature ranges -40 – 120°C, humidity range 10 % to 98%, capacity 200 l,

– single-column tensile machine with load up to 5 kN.

Case study:

Case Study 1: Consumer Electronics

A consumer electronics company, aiming to ensure the longevity and reliability of its new line of portable devices, partnered with the Department of Printed Electronics, Textronics, and Assembly to focus on specific surface mount operations coupled with tensile testing. The objective was to refine their surface mount technology processes, particularly in the bonding of components to the flexible PCBs, and then rigorously assess the strength and durability of these connections using the department’s advanced tensile testing facilities. This collaboration enabled the company to significantly enhance the mechanical integrity of their device components, ensuring they withstand everyday use and stress, which in turn led to an increase in consumer trust and product lifecycle.

Optional:

[1] Lepak-Kuc, S. (2023). low-temperature silver-based ink for highly conductive paths through industrial printing processes suitable for thermally sensitive substrates and beyond. Journal of Materials Research, 39(2), 297-310. https://doi.org/10.1557/s43578-023-01223-2.

[2] Raczyński, T.; Janczak, D.; Szałapak, J.; Lepak-Kuc, S.; Baraniecki, D.; Muszyńska, M.; Kądziela, A.; Wójkowska, K.; Krzemiński, J.; Jakubowska, M. Influence of the Heat Transfer Process on the Electrical and Mechanical Properties of Flexible Silver Conductors on Textiles. Polymers 2023, 15, 2892. https://doi.org/10.3390/polym15132892.

[3] Scenev, V., Szałapak, J., Werft, L., Hoelck, O., Jakubowska, M., Krshiwoblozki, M., … & Schuster, M. (2022). low‐temperature processible highly conducting pastes for printed electronics applications. Advanced Engineering Materials, 24(9). https://doi.org/10.1002/adem.202101752.

Access Provider / Facilities