Wet processes

About

We offer efficient and reproducible wet cleaning processes of photomasks and substrates, as well as wet etching of materials.

Description

We offer cleaning of silicon substrates, quartz substrates and photolithographic masks (single wafer mode). A megasonic rinsing system is used to remove sub-micrometer particles, together with a system for discharging accumulated electrostatic charge. Cleaning carried out in a dry-in/dry-out system. Efficient and reproducible process.

We also offer efficient and reproducible processes of cleaning large batches of substrates. Wet etching of different layers in batch mode is possible. Cleaning and etching carried out in a dry-in/dry-out system.

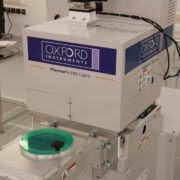

Available tools: AP&S SpinMask 300, 2 x Siconnex batch spray.

Technical specifications:

Single wafer cleaning processes:

- silicon and quartz substrates with diameters of 50 mm/2″, 100 mm/4″, 150 mm/6″, 200 mm/8″,

- photolithographic masks with dimensions of 2.5″ x 2.5″, 5″x 5″, 7″ x 7″, 9″ x 9″.

Types of processes:

- SPM (Sulfuric Peroxide Mix) a mixture of H2SO4 and H2O2 to remove organic contaminants,

- SC1 (Standard Clean 1) a mixture of NH4OH, H2O2 and deionized water to remove organic contaminant ions,

- SC2 (Standard Clean 2) a mixture of HCl, H2O2 and deionized water to remove metallic impurities ions.

Efficient and repeatable processes of silicon substrate cleaning performed on 100 mm/4″, 150 mm/6″ and 200 mm/8″ substrates in batch mode (up to 25 substrates). The processes include:

- SPM cleaning,

- SC1 cleaning,

- SC2 cleaning,

- removal of native SiO2 in dilute HF solution.

Wet etching of a variety of layers:

- silicon dioxide layers,

- poly- and monocrystalline silicon layers,

- silicon nitride and silicon oxide layers,

- thin metallic layers – e.g., aluminum, titanium and others.

Wet etching processing of 100 mm/4″, 125 mm/5″, 150 mm/6″ and 200 mm/8″ substrates in batch mode (up to 25 substrates).

Case study:

A user would like to clean wafers for further processing or etch the deposited material layers in a controlled manner.

Access Provider / Facilities